Effective duct design is a main component of your HVAC system. It directly impacts energy efficiency and occupant comfort. Well-designed ductwork promotes smooth and quiet airflow, ensuring it reaches every room efficiently.

This lowers energy costs and improves indoor air quality.

However, achieving optimal airflow is not about buying top-tier equipment. It requires a thorough understanding and careful system design.

In this post, Season Control HVAC explains the key strategies for designing ductwork that optimizes airflow. Let’s boost efficiency and functionality together.

Fundamentals of Airflow Dynamics

Airflow within ductwork is influenced by several factors, including duct shape, size, and the physical properties of the air being moved.

An understanding of how these elements interact helps design a system that optimally distributes air.

Airflow Principles

Air moves from areas of higher pressure to lower pressure. Controlling the speed of this movement, known as air velocity, can prevent inefficiency and noise in the duct system.

The duct design should aim to minimize sharp bends and obstructions that can create turbulence—disturbances in the airflow that lead to increased resistance and noise.

By using smooth, well-calculated transitions and turns in the ductwork, one can reduce turbulence and improve overall system efficiency.

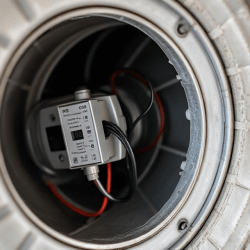

Designing Duct Shape

Circular ducts are generally more effective at promoting smooth airflow than rectangular ones.

The fewer flat surfaces and sharp angles there are, the less opportunity for air resistance and turbulence. This design choice helps maintain consistent airflow and reduces the energy required to push air through the system.

Duct Sizing

Proper duct size helps maintain the right air velocity.

Oversized ducts can lead to low air velocity, causing poor air distribution and increased heating or cooling costs due to inefficiency. Undersized ducts, on the other hand, can cause increased pressure and noise due to the high air velocity.

Calculating the correct duct size based on the cubic feet per minute (CFM) of air required in each room ensures efficient operation.

Thermodynamics

Understand how heat transfers within an airflow system.

Efficient ductwork should minimize unnecessary heat gain or loss as air travels from the HVAC unit to various building parts. This can be achieved by strategically placing ductwork away from areas prone to temperature extremes, such as unconditioned spaces or external walls.

Additionally, incorporating proper thermal insulation around ducting reduces heat loss in winter and heat gain in summer. This maintains the desired temperature of the conditioned air throughout its journey.

Material Impact

The choice of ductwork material impacts its ability to insulate and preserve the conditioned air’s temperature.

Materials such as fiberglass duct boards and insulated flexible ducts have good insulation properties, which help maintain temperature control and improve energy efficiency. These materials also reduce noise from the airflow.

However, they must be properly installed to avoid common issues like condensation and mold growth, which can occur if air leaks at the seams. Metal ducts, while more durable and less susceptible to mold, often require more insulation to achieve similar levels of temperature preservation.

Proper Installation Practices

A properly installed ductwork is necessary to maintain the efficiency and effectiveness of an HVAC system.

Pre-Installation Planning

Begin by thoroughly assessing the building’s layout and each space’s heating and cooling needs. Include detailed calculations to determine the optimal size and configuration of ducts.

Ensure that ductwork installation is coordinated with other building systems, such as electrical and plumbing, to avoid conflicts that compromise the ductwork’s integrity or accessibility.

Installation Techniques

Use high-quality sealants to ensure all joints and seams in the ductwork are airtight. Proper sealing is essential to prevent air leaks, which can decrease system efficiency.

Apply adequate insulation around ducts, especially in unconditioned spaces like attics or basements, to prevent heat loss or gain. This helps maintain the air temperature as it moves through the ducts, reducing energy waste.

Install proper supports to keep ducts in place and avoid sagging or bending, which can restrict airflow. Ensure there is sufficient space around ductwork for installation and future maintenance.

Use of Proper Tools and Materials

Choose durable materials suitable for the specific requirements of the environment where they are installed. For example, use rigid ducts in areas where they might be exposed to damage and flexible ducts in tight spaces that require adaptable materials.

Utilize the correct tools for cutting, shaping, and securing ductwork. This precision contributes to the overall quality and durability of the installation.

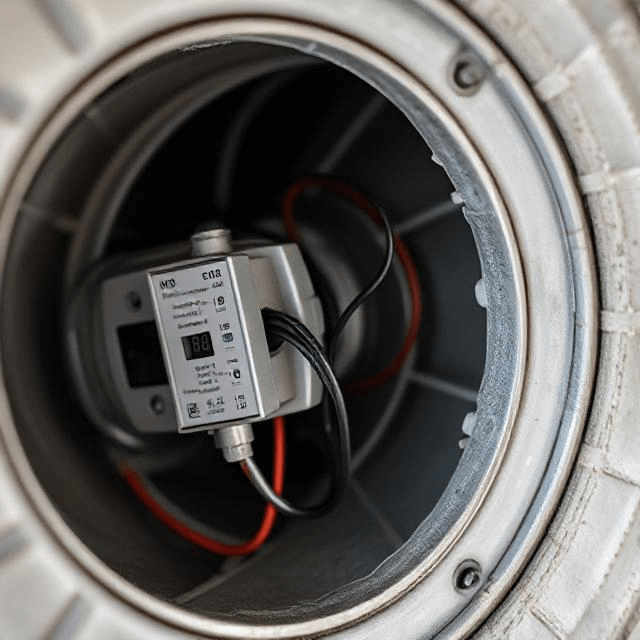

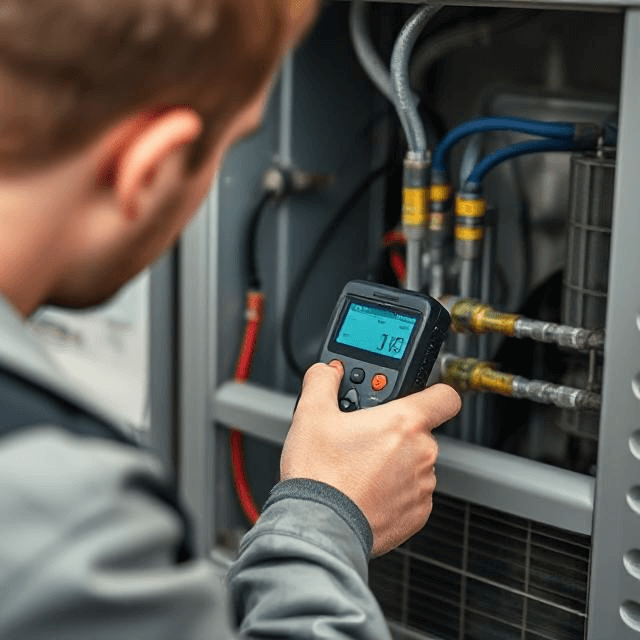

Testing and Commissioning

After installation, conduct a leak test to ensure there are no air leaks. This can be done using smoke pencils or a duct blaster.

Adjust the dampers to balance the system, ensuring even air distribution throughout all rooms. This step might require measuring airflow at different vents and adjusting to optimize performance.

Compliance and Documentation

Ensure all installations meet local building codes and HVAC standards, which can vary by location. This includes adherence to safety standards and environmental regulations.

Keep detailed records of the installation process, materials used, and ductwork configuration. This documentation is invaluable for future maintenance or modifications.

Common Pitfalls in Ductwork Installation

Even with the best intentions and planning, certain common pitfalls can compromise the effectiveness of ductwork installations. Recognizing and avoiding these issues maintains an HVAC system’s integrity and efficiency.

Here’s a look at some frequent mistakes and how to prevent them:

Improper Duct Sizing

- Issue: Ducts that are too large or too small can lead to poor air distribution, increased energy consumption, and system strain.

- Prevention: Use precise calculations based on each room’s heating and cooling requirements to ensure the right balance of air velocity and volume.

Inadequate Sealing

- Issue: Joints, seams, and connections that are not properly sealed can lead to significant air leaks.

- Prevention: Employ high-quality sealants and ensure every joint is thoroughly checked and sealed during installation. Regular inspections post-installation can also catch and rectify any deterioration in seals.

Neglecting Insulation

- Issue: Failing to insulate ductwork, especially in unconditioned spaces, results in heat loss or gain, reducing system efficiency.

- Prevention: Wrap ducts with appropriate insulation materials and ensure no gaps or compression points might compromise the insulation’s effectiveness.

Ignoring Manual D Guidelines

- Issue: Not following the ACCA’s Manual D for duct design can lead to inefficiencies and performance issues.

- Prevention: Adhere to the standards outlined in Manual D for residential duct systems, which provide comprehensive guidelines for designing and installing ductwork.

Poor Placement and Routing

- Issue: Incorrectly placed or routed ductwork can cause unnecessary bends and length, which reduce airflow and system efficiency.

- Prevention: Plan the ductwork layout to be as direct as possible. Avoid sharp bends and long runs that can increase resistance and reduce the efficiency of air movement.

Lack of Access for Maintenance

- Issue: Ductwork that is hard to access for maintenance or repair can lead to decreased performance over time.

- Prevention: Design the system with access panels and spaces, allowing easy inspection and maintenance. Adhere to regularly scheduled maintenance to ensure that the system remains clean and efficient.

Failure to Test and Balance

- Issue: Not testing the system for leaks and balance after installation can result in uneven air distribution and inefficiencies.

- Prevention: Upon completion of the installation, perform thorough testing and balancing to ensure the system operates at its optimal capacity across all areas it serves.

Final Thoughts: Enhancing HVAC Efficiency with Expert Duct Design

Effective duct design helps achieve optimal airflow, which enhances energy efficiency and occupant comfort. Proper installation and maintenance are key to ensuring the long-term success of any HVAC system. Regular inspections and adherence to design guidelines can prevent common issues that compromise system efficiency.

Contact Season Control for HVAC system advice and custom solutions. Our team is ready to assist you in optimizing your HVAC system for better performance and energy savings.